Research at University West in Sweden is propelling additive manufacturing (AM) towards critical use in the aviation industry, a sector striving to diminish its environmental footprint. Dr. Karthikeyan Thalavai Pandian’s recent doctoral work focuses on integrating AM, specifically electron beam powder bed fusion (PFB-EB), with titanium alloys into aviation applications.

Additive manufacturing is already employed in aircraft engines, though primarily for non-critical parts. GKN Aerospace, however, is exploring its potential for broader application, including critical components, which necessitates rigorous research and testing due to the stringent safety and quality standards of the aviation sector.

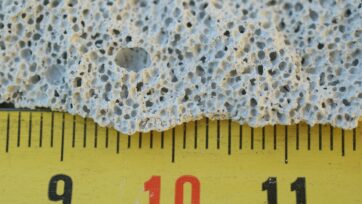

Dr. Pandian’s dissertation, presented in late May, centers on the titanium alloy Ti-6Al-4V, commonly used in the cooler sections of aircraft engines for its high specific strength. His work aims to enhance the fatigue properties of materials produced with PFB-EB. “The challenge with AM technologies like PFB-EB is that surface imperfections and internal defects from the manufacturing process can significantly impair the fatigue life of components,” Dr. Pandian explains. He has specifically investigated how various PFB-EB process parameters affect surface roughness and, subsequently, the fatigue properties of these components.

The standard post-build heat treatments used in traditional manufacturing do not align well with the needs of AM-produced parts, often weakening the static strength of the titanium alloys. Dr. Pandian has explored alternative heat treatment methods that operate at lower temperatures to maintain static strength while ensuring the fatigue properties remain intact. This new approach aims for standardization to meet the aviation industry’s rigorous criteria.

Beyond the technical aspects, Dr. Pandian is also focused on reducing the need for post-processing in AM. By improving the surface quality of AM components, the goal is to minimize post-build machining, saving both materials and manufacturing time. “Reducing the machining depth from approximately 2 mm to 1 mm not only conserves resources but also moves us closer to producing components that are ‘net-shape’—a term used to describe parts that require no further processing post-manufacture,” he states.

Now a senior lecturer at University West, Dr. Pandian is expanding his research to explore more AM processes and materials, with a continued emphasis on fatigue properties and quality assurance through artificial intelligence. Reflecting on his journey from a product developer at Volvo Construction Equipment in India to academia, he is enthusiastic about the potential of material science research to revolutionize manufacturing. “After eleven years as a product developer at Volvo Construction Equipment in India, I needed to understand how the properties of materials affect the final product. Now, after completing my doctoral studies, I am convinced that more research in materials science can make a big difference,” Pandian concludes.

References

University West, 2023, ‘Taking additive manufacturing one step closer to the aviation industry goals’, TechXplore, viewed 21st June 2024, <https://techxplore.com/news/2024-06-additive-closer-aviation-industry-goals.html>